FRP Skylight Roofing Profile Sheets

Roofclad has been manufacturing superior grade Fiberglass and Polycarbonate roofing and Cladding products, translucent, clear and opaque finish for all kinds of Industrial Warehouse, Residential, Commercial buildings and open sheds. A naturally well lit building of any kind that is bright and with full of soothing light seems more in touch with Mothers Nature, when you allow all the natural Sunshine goodness inside the building. Natural light is very important in creating condusive environment for educational, residential & industries, always resulting in better achievements and higher productivity. In short, it is an undisputed fact, that people are happier and productive in buildings that are naturally lit. Moreover, with the recent focus on sustainability and reduction of every day consumption and CO2 emission, the benefits of roof lighting have become compelling and forms very important part of any building in terms of utility, application, architectural and aesthetic looks along with sustainability and durability of the Skylight Product being used. Hence, the selection of rooflight product becomes very important and sometimes an architectural choice, but is usually more influenced by the roof system in terms of geographical location, application, durability, looks and environment.

Types of different Durable Rooflight Products:

1. FRP Roofing Products- Available in Clear & Color Translucent Sheets and opaque Sheets in plain & embossed finish.

2. Polycarbonate Roofings products – Clear & Color Translucent Sheets in plain & embossed finish.

FRP Roofing System

FRP Skylight Sheets is a wonder composite material consisting of Fiberglass reinforcement in a matrix of UV Stabilized unsaturated polyester sheet grade resin system forming a tough laminate in desired profile having exceptional strength to weight ratio. FRP offers almost unlimited possibilities for shape, size, profile and color and known for its high strength, durability, water/chemical proof, dimensional stability, high resistance to environmental corrosion due to extremes of temperature

and weather including emission of natural and Industrial Chemical fumes. FRP Sheets are light in weight, good aesthetic appeal, easy to install and maintain. We at Roofclad are manufacturing FRP Sheets using State-of-the-Art sandwitched molding process resulting in excellent smooth glossy surface finish.

Range & Types of FRP Roofing Sheets UV Stabilized:

1. FRP Translucent Skylight Roofing & Cladding Sheets for industrial Building as per IS 12866.

2. FRP Translucent or Pigmented Opaque Chemical resistant Sheets for Chemical Industry.

3. FRP Translucent or Pigmented Opaque Sheets for Buildings in Corrossive Environment of Coastal Area.

4. FRP Weather Resistant sheets & panels for Cooling Towers as per CTI – 131.

5. FRP Weather Resistant & Fire Retardant Gelcoated Sheets in desired color for any customized roofing or other application.

Note: We at Roofclad have Complete Technical expertise to manufacture FRP Sheets customized to match the requirements, specifications & applications in any profile.

Annual Capacity: With dedicated and motivated skilled force, having state-of-the-Art manufacturing facility and factory area spread over more than 30,000 sq. ft., annual capacity for manufacturing of any kind of FRP Sheet is 250,000 sq. mtr. Approx.

FRP Chemical Resistant Sheets

Technical Note on FRP Chemical Resistant Sheets for Industrial Building Roofing or Cladding

Industrial Roofing and Cladding are exposed to extremes of weathering conditions, water, chemical fumes or chemical environment and constant exposure to humid conditions. Under these conditions Roofing & Cladding are prone to corrosion and selection of Roofing material should be done accordingly.

Normally, Color Coated Profile Metal Sheets in 0.5 mm thickness are used for roofing in combination with FRP Skylights, FRP Gutter, Turbo Ventilator and Accessories under normal weathering and environmental conditions. In general, Mild Steel are highly corrosive material even under normal environmental conditions but the same is color coated with few microns of weather resistant paints which has very limited self life. But in presence of harsh weathering, chemical fumes or coastal environments, the M.S. Color Coated Profile Sheets are under constant threat of corrosion and not recommended for Roofing taking into consideration of minimum 10 years self life.

FRP Skylight / Chemical Resistant Sheets is a Fiber Glass Reinforced u/v stabilized unsaturated Polyester resin system composite material consisting of a network of reinforcing glass fibers embedded in a matrix of thermosetting resin. FRP offers almost unlimited possibilities for shape, profile, size and color, which is known for its high resistance to wreathing & environmental corrosion, chemicals, fumes with inherent property of high strength, durability, water, chemical proof, light weight, dimensional stability, aesthetic appeal and easy to install and maintain.

At Roofclad we are India’s First Manufacturer to have developed special process for manufacturing of FRP Chemical Resistant Sheets, in which two step special coating is done to provide maximum resistance against most of the harsh chemicals at elevated temperatures and retaining the mechanical properties of the sheet. The said sheets are custom made in any required profile and in transportable length. Due to two step protection against corrossion the sheet has enhanced life of more than 15 - 20 years and are best suited and recommended roofing sheets under these circumstances and to replace the conventional roofing system which used to weather out and corrode very fast and required heavy maintentance periodically.

Life cycle costs of FRP Chemical Sheets are very economical as compared to other conventional roofing material due to above said properties of the sheets.

Properties & Advantages

a. Excellent corrosion resistant from all kind of alkali, acid, chemical fumes, coastal environment, water and extremes of weather & temperature.

b. Superior Tensile Strength – FRP Sheets has very high tensile strength to weight ratio.

c. Thermal Properties – FRP Sheets have a low co-efficient of thermal expansion with compatible co-efficient of expansion and contraction vis-à-vis PEB/M.S. Structure.

d. Dimensional Stability – FRP Sheets do not shrink or stretch within the limits of their strength even during long period of use.

e. Electrical Characteristics – FRP Sheet has high di-electric constants.

f. Considerable Design Versatility – Can be molded to match your profile in any transportable length.

g. The said FRP Chemical Resistant sheets are available in Translucent & Opaque colors.

h. Barcoal Hardness, water absorption, Fiberglass content & light transmission as per IS – 12866.

i. Shatter and hail storm resistance sheet.

j. High impact resistant sheet.

k. Light weight and unbreakable.

l. Environment friendly.

m. Flexibility in sizes, color and thickness (as per span of Purlins)

n. Maintenance free, easy to handle and install.

o. Fire-retardant properties if required.

p. Very long life — 15-20 years with anti-ageing film.

FRP Panel Sheets for Cooling Tower

Cooling Tower Institute, an International body constituted to lay down the complete standards for various parts and products to be used in various kind of Cooling Towers. CTI - 131 is the standard for manufacturing of FRP Panels and sheets for Cooling Towers and we at “Roofclad” are the pioneers in making of high quality GRP/FRP Panels in required profile and length strictly in compliance with drawings and specification provided and in accordance with CTI - 131 standard.

APPLICATIONS IN COOLING TOWERS

1. Fiberglass Reinforced Plastics profile Panels as Louvers.

2. Fiberglass Reinforced Plastics profile Panels as Cladding.

3. Fiberglass Reinforced Plastics profile Panels as Internal/ Partition Walls between the fills.

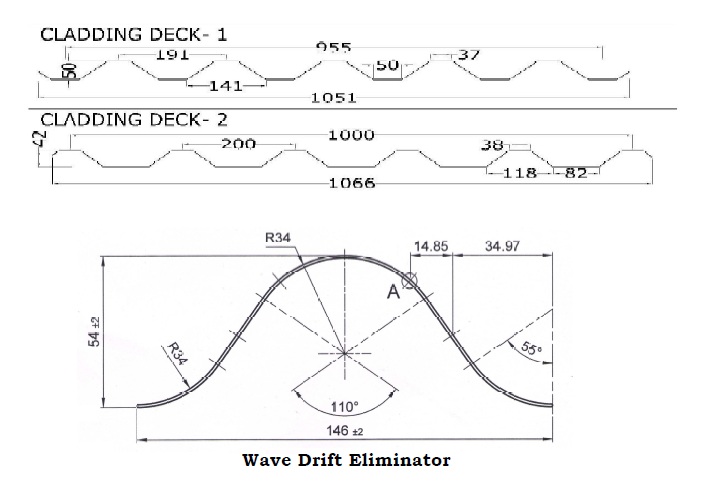

4. Fiberglass Reinforced Plastics Wave Drift Eliminators

DRAWING & LAYOUT

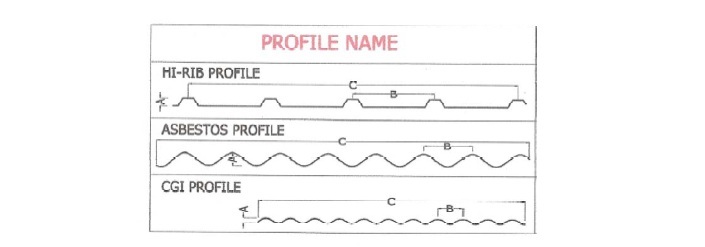

Standard Louver / Cladding Panel Profile Sheets

Fiberglass Reinforced Plastic Panels are manufactured in accordance with standards like IS: 12866 / CTI – Std. 131 as agreed with the clients in their respective standard profile drawing and specifications including material of construction. The relevant tolerances are as per standards or in case of any deviation shall be in agreement with the said manufacturer. Most commonly used standard drawings are given above, as Cladding Deck Profile 1 & 2 and if required we are competent to develop and supply the product in any profile and length as desired/ specified by the manufacturer.

Tolerance on length and width shall be ± 6mm

Tolerance on given dimension shall be ± 1.5mm

Tolerance in density ± 5% (from the mean density)

Tolerance in pitch and depth of the profile ± 1.5mm (per foot of panel width)

Complete approved BOQ along with detailed specification and drawing to be provided by the manufacturer before start of manufacturing. If required one sample to be approved for all parameters before start of bulk production which will be in accordance with the approved sample and specifications.

THICKNESS & WEIGHT

Thickness and Weight of the FRP Cladding Panels shall have values as per below details :

Nominal Thickness : 1.5 mm (Minimum, Based on flat material)

Nominal Weight : 8 oz/sq. ft or 2.44 kg /m2 (Minimum, Based on flat material)

Tolerance on weight shall be ± 5%.

The above given thickness and weight requirement are applicable for a support structure having span dimension less or equal to 2000 mm and max wind pressure less or equal to 1.3 kN/m2. FRP Panels are available from 1 mm thickness to 3 mm thickness maximum.

The thickness of sheet and corresponding weight are customised corresponding to structure span, wind pressure and geographical location and the selection for the

same shall be in mutual agreement with the Cladding manufacturer and the Client. The complete drawing and specification shall be duly approved by the end user

before fabrication of the said material.

GENERAL INFORMATION & SPECIFICATION

1. Panel Construction: Material for reinforcement can be Chopped Strand Mat / Owen Roving Glass using suitable grade UV stabilised Isophthalic Gelcoat (optional) and impregnated with UV stabilised FR grade Isophthalic Polyester Resin and permitted fillers.

2. Flame Spread : FRP Cladding Panel with flame spread rate less or equal to 25, according to ASTM E-84 (any customised requirement shall be communicated to the panel manufacturer with complete specification).

3. Panel Configuration : As per Client’s drawing. Lead time for making of mould for any new profile is maximum 15 days.

4. Color : Normally preferred color is light grey as per RAL 7035. Any color of your choice can be given as per RAL color shade card.

5. Finish : Surface finish shall be smooth and glossy. Embossed surface can also be supplied.

6. Nominal Weight and Thickness:

*Note: Above Sheet thickness in profiled formation are average thickness corresponding to the said weight.

7. Glass Content : Minimum 25%

8. Extreme Ambient Properties : Extremes of temperature, weathering condition, exposure to chemical fumes, geographical location (coastal areas), sun radiation, etc. to be informed with details of temperature, humidity, pH value and environmental conditions so that the panels can be manufactured accordingly.

9. Light Transmission : The nominal light transmission factor of opaque cooling tower panels shall be 5 % or less (or as agreed between the manufacturer and client) when tested in accordance with ASTM D-1494 or similar norms.

10. UV Protection : All polyester resin and gelcoat used shall be UV stabilised.