PUF Insulated Composite Panels

Pre-fabricated Composite Panels or Insulated Panels for Roofing & Cladding are Sandwich Panels manufactured with profiled Color Coated Metal Sheets or FRP / GRP Profiled Sheets duly Sandwiched with PUF (Polyurethane Foam) as the insulation material.

The Panels are available in various colors and total thickness of panel range from 30 mm to 100 mm. The PUF Panels are ready-to-install and self supporting with high overall stiffness.

Advantages & Essential Features

1. Very high thermal insulation – Superb thermal efficiency & rigidity.

2. Ready-to-Install and self supporting. (PUF Panels are Load Bearing Sheets)

3. Inner and outer skin in Pre-coated GI / Galvalume / FRP Sheets are resistant to extremes of Weather & corrosion.

4. Very light weight to high strength ratio.

5. Ease of handling & installation.

6. For Roofing & Cladding provision of specially designed overlap system to ensure water leak proof & airtight joints.

7. Vertical & horizontal Panels are provided with Tongue & groove joints to ensure air tight assembly.

8. Monolithically Constructed Panels, hence saving on support structure, no use of wire mesh or loose insulation / Glass wool to be fixed separately and ease of handling & installation with less of labour.

9. Withstand against storm, heavy rainfall, wind.

10. Sturdy enough for temperature (-180°C to +140°C).

11. Fire retardant and Self extinguishing.

12. Low maintenance.

Applications

1. Industrial Building & Sheds – Automobile, chemical, steel, cement, power plants, pharamaceutical, commercial building, godown, etc.

2. Telecom Shelters

3. Cold Storage & rooms.

4. Pre-fabricated Shelters / Defense Shelters.

Range of Insulated Composite Panels

1. Insulated Roofing & Cladding Panels for pitched Roofs with minimum slope of 7 – 8%.

2. Insulated Roofing & Cladding Accoustic Panels.

3. Insulated Wall Panels with Tongue & Groove jointing system for use in Industrial, commercial, refrigerated rooms & Cold Storage.

4. Fixing accessories like flashings, corner joints and customized fittings.

Details of Insulated Composite Panels

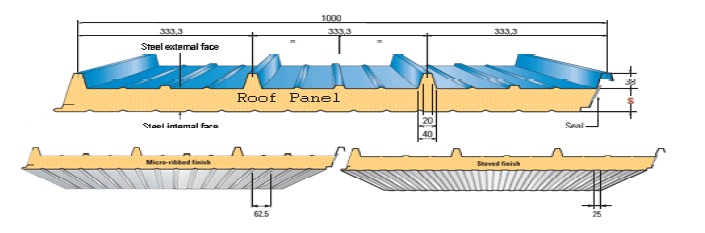

Insulated Roofing & Cladding Panels are self-supporting Metal panel for pitched Roofs with minimum slope of 7 – 8%. Normally, recommended thickness for Top exposed external face in steel is 0.5 (TCT) mm and internal face in steel is 0.4 mm. The Top & Bottom sheets can be replaced as per utility in corrossive environment with FRP in 2 mm & 1.5 mm thick sheets respectively. The insulation used is PUF (Polyurethane).

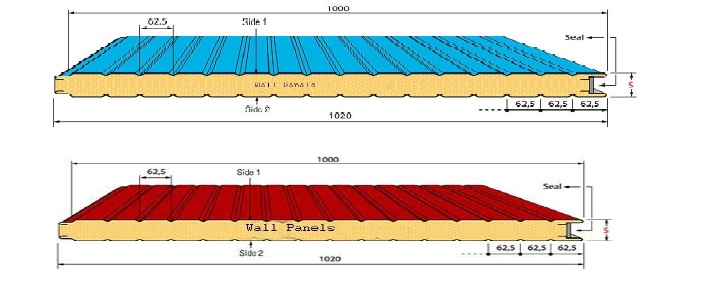

Insulated PUF Wall Panels with Tongue & Groove air tight jointing system which are self supporting panels for use in Industrial Building Partition, Telecom Shelter, Cold Storage, Defense Shelters, Porta Cabins, High Altitude Cabins, Commercial Buildings etc.

Fixing accessories like flashings, corner joints and customized fittings. All the above panels are available in required thickness as per customers requirements and site conditions. All necessary standard accessories are provided for proper fixing & erection of complete system.